Our Ten Point Quality Control begins in the field at Kuhn Hay. In addition to the farmers own entomology inspection, a Kuhn Hay Field Foreman will walk the field to ensure there are no foreign materials in the cuttings. Our Field Foreman will also conduct a visual inspection for insects and disease. His inspection is logged in our Field Comment Form.

After baling, our Stack Quality Supervisor will collect samples of your product and send them to laboratories to test for nitrate levels and diseases. We can send your product to a second laboratory for a nutritional analysis should you desire. Our Stack Quality Supervisor will also conduct an initial moisture content analysis.

Kuhn's highly respected Field Grading Team will then confirm the grade of your product for palatability, color, stem size, leaf quality and texture. The Team will grade and mark each stack, perform a second moisture analysis and enter all of the data into a Field Grading Sheet. The team can also collect samples and ship them to you should you desire.

Kuhns Trucking Supervisor will separate your stacks in the field based on grade to ensure each container is packed with consistent quality. He will also perform a visual examination of the top, bottom, and sides of each stack to check for any contamination and will conduct a third moisture analysis.

Kuhns Trucking Supervisor will supervise the loading of your product on our tractor-trailers to ensure your stacks are loaded by proper grade. He will provide our Trucking Destination Order to everyone who transports your product to confirm it is properly loaded and stored by grade and lot.

Our Ten Point Quality Control Manager and his team will perform a Secondary Grading as each stack arrives at our storage yard. His report is then compared with the Field Grading Report to ensure our grading is accurate and consistent. The manager will then supervise weighing on our scale and will perform a fourth moisture analysis. Finally, our Ten Point Quality Control Manager will confirm your product is storage precisely as you have specified.

Our De-stacker Operator will perform a visual inspection of the stack to check for contamination before it enters the de-stacker. He will then conduct a fifth moisture analysis and will check tags to confirm that your specific product is entering our press. After separation, the De-stacker Operator will check moisture again and will perform a visual inspection of each bale as it moves down the chute. He will remove any with contamination. The De-stacker Operator will then place a Stack Change Sheet on the last bale of each stack.

The Kuhn Hay Press Foreman will inspect all compressed bales and will flag any that show signs of contamination. These bales will be removed. Our Ten Point Quality Control Manager will then collect a sample from each booking, bag it, and store it in our vault. This ensures the hay we shipped you is the exact grade and quality you specified.

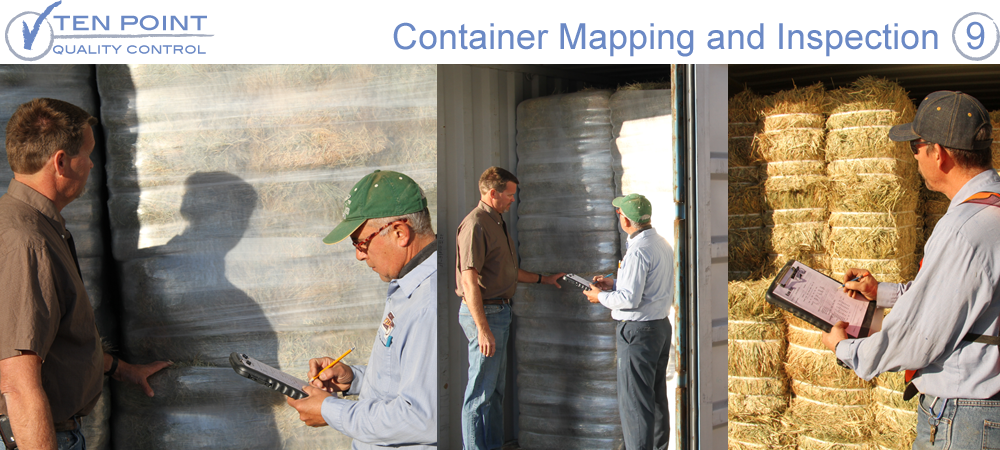

The Ten Point Quality Control Foreman will monitor loading of the container to ensure your product is loaded according to your grade, stack, and packaging specifications. He will note the specific loading process on our Container Map Form. Finally, Kuhn Hays General Manager and Ten Point Quality Control Manager will inspect for proper bale shape and packaging quality.

Our Ten Point Quality Control Manager and our Yard Container Supervisor will then perform a final visual inspection to note the appearance, brightness, and palatability of your product. They will weigh your container and confirm it was properly loaded. Finally, they will place a seal on it, and note all of their observations in our Quality Control Summary Form.